Pala Diamond Co. Precision Tolerance

Pala Diamonds proudly offers craftsmanship and attention to detail

When you are passionate about producing exquisite bespoke jewellery, design is only one part of the process; selecting top-quality materials and gemstones is also vital. When you have chosen the clarity and colour you need, why accept less than the best when it comes to the cut?

Creating fine jewellery needs more than an availability of raw materials. You need carefully selected, precisely cut gemstones. The more uniform the diamonds, the greater the potential for refined and expertly crafted jewellery.

We have over five generations of expertise in the diamond trade. Our family business began in India, then continued in Kenya and London, before reaching the Birmingham Jewellery Quarter. As proud members of the jewellery trade for over 170 years, we understand the issues that jewellers face in sourcing diamonds that are consistent in size, weight and quality.

While history has given us a mastery in craftsmanship, we offer the future of diamond cutting through our state-of-the-art technology and refined screening and sorting processes. Pala Diamonds have established an excellent reputation for precision measurement tolerance for fine jewellery optical diamond setting.

How does precision tolerance cutting benefit jewellery manufacturers?

Uniformity is key to crafting fine jewellery. To create a beautiful design, you need a selection of melee diamonds, matched in cut, clarity and colour.

However, this isn’t simple. Buying diamonds from multiple sources can be difficult; delays are caused by sifting through each packet to identify matches and returning the rest; the process creates extra deliveries, additional paperwork, greater courier costs; you’ll spend your time sorting, when you could be creating. Following this strategy means that the more unique or technical the cut you need, the harder it will be to find the perfect stones.

Ordering from Pala Diamonds removes these issues. Our precision cutting service delivers exactly what you need – consistently.

Pala Diamonds precision cutting service improves the efficiency of your diamond sourcing

We use state-of-the-art technology and trusted suppliers to create our assortments of melee diamonds.

Sourcing your diamonds from Pala means:

– Every diamond in your parcel is cut to exact measurements with tight tolerances

– Every diamond has controlled measurement, tolerance and depth, as specified

– Our Top Make diamonds are all cut, polished and finished in the same factory for consistency

– Every diamond goes through our two-stage quality control process, with polishing completed once in the factory, and then again at the Pala Diamond Company

For jewellery manufacturers, this means

– The efficiency in your manufacturing process is improved

– Excess costs are reduced

– The overall finish and look of your fine jewellery is improved

– You can deliver bespoke pieces to the customer quicker

Slight differences in diamond weight can increase your costs per stone. In quantity, that can make significant losses. You could also argue that precision cutting adds cost per stone, but we’re confident that the quality of cut and the enhanced appearance will yield a finer piece of jewellery.

Ultra Precision Diamond Cutting™ – for those who need absolute precision

For fine jewellery, high jewellery or bespoke designs, we take precision cutting to another level. The Pala Diamond Ultra-Precision Diamond Cutting™ process has been developed and refined over years of trial and innovation. With this process, we can push boundaries and help you to exceed your design aspirations.

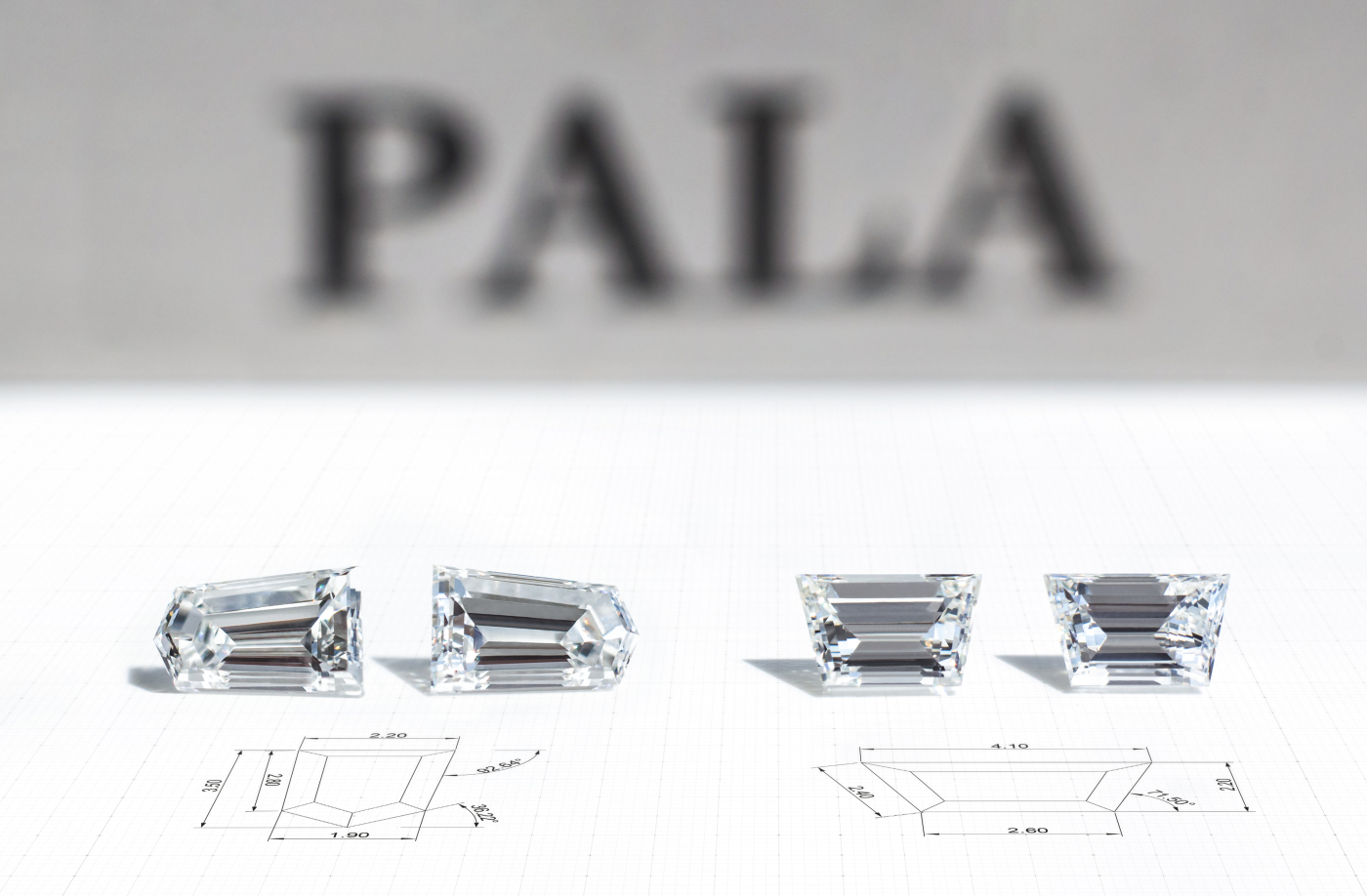

Meeting the most rigorous requirements of leading jewellery houses, we deliver meticulous consistency and excellence for complex and unique diamond jewellery projects. Ultra Precision Diamond Cutting™ is an advancement on our Precision cutting and Cut-to-Order service, producing lines of diamonds without any compromise in quality of cut or calibration across diamond measurement tolerances such as depth, girdle and other diameters. This ensures that every stone is exactly the same.

Compare the precision in Pala Diamond Cutting

When we’re talking about precision cutting, every sliver of a millimetre counts.

Regular tolerances in the UK market allow for +/- 0.10mm. We feel this is a low standard for quality jewellery and lacks a certain aesthetic; it also incurs additional cost for excess weight on larger diamonds. Specific cuts like the step cut are particularly unforgiving, being more visible to the naked eye in a matched line or layout.

Our rough diamond planning, manufacturing and sorting processes offer some of the tightest controlled measurement tolerances available.

Pala Diamonds Standard cuts:

– Step-cut layouts of emerald, Asscher and baguette with a tolerance of +/- 0.07mm

Pala Diamonds Precision cuts:

– Round diamonds with a tolerance of +/- 0.025mm (twenty-five thousandths of a millimetre) as standard

– Step-cut layouts of emerald, Asscher and baguette with a precision tolerance of +/- 0.02mm length/width for the perfect calibrated line

Pala Diamonds Ultra-Precision Diamond Cutting™:

– All of our Ultra-Precision Cut diamonds are shaped meticulously from carefully planned and mapped rough natural diamonds, not from recut polished stones

– +/- 0.015mm tolerance for length, width and depth at tightest

– We apply the strictest tolerance to girdle, table and crown height percentages, as well as lower-half lengths – ensuring absolute uniformity from stone to stone

Do you need Ultra-Precision?

Ultra-precision cutting is not necessary for every project. It’s an option when absolute precision is key – for watchmaking or the very finest of mosaic style diamond settings, and perhaps for rare, obscure or proprietary cuts or the very finest traditional cuts on high jewellery or objet d’art.

When you’re creating a distinct and exquisite piece, you might need to take that step to perfection by seeking quality, uniquely shaped and rarer diamond products. You’ll have jewellery that commands top prices, is harder to replicate and stands out from competitors.

Why choose Pala Diamonds?

Our experts will work with your jewellery designers and setters as in-house consultants for your project, with no obligation.

Send us your design or CAD drawing with any desired cut proportions for table, depth, crown, height and so on. We will produce technical drawings for your consideration.

Every project with us assures the following:

– No parcel mixing. Our Ultra-Precision diamonds are 100% planned and cut from rough

– Advanced in-house screening using De Beers technology for 100% natural diamonds

– A UK-based company for easier communication, smoother logistics, straightforward banking and terms or credit

Our extreme attention to detail ensures an unparalleled uniformity of diamond lines. Your end product will have breathtaking optical performance, leading the market with the highest levels of craftsmanship and precision available.

For more information about our Cut-to-Order and Ultra-Precision Diamond Cutting™ options read our blog, or speak to our gemologists.